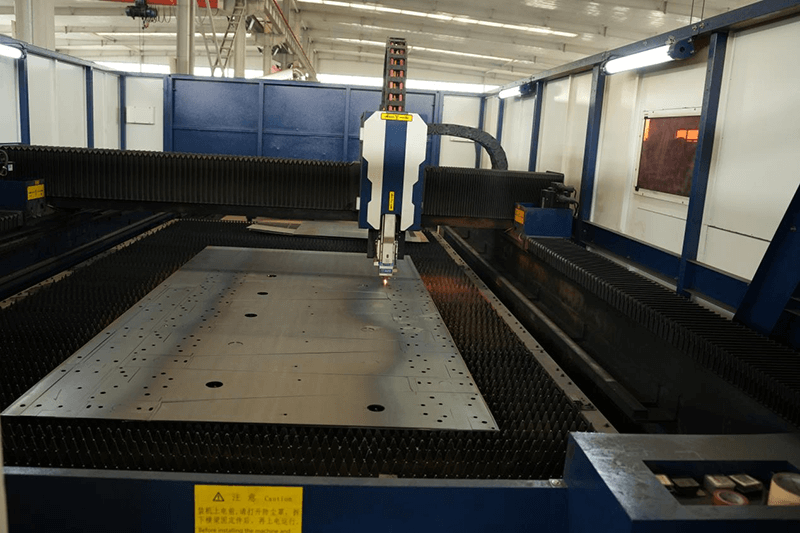

Recently, our cooperative factory introduced a batch of intelligent welding robots, such intelligent robots have helped us make better quality products and improve production efficiency and quality.

The automation and intelligence level of welding process is mainly reflected in the development level of welding robot technology. The operator moves each joint of the robot in the rectangular or polar coordinate system, moves the soldering moment along the welding track, records the position, soldering moment attitude, motion parameters and process parameters on the soldering moment path, and generates continuous teaching procedures for all operations.

This kind of robot does not have the workpiece assembly error, thermal deformation in the welding process environment change, as well as the work object change should ability, therefore, develop a new generation of has a variety of sensing function, can automatically formulate trajectory, welding moment attitude and welding parameters of intelligent robot will become the main development direction.

The development of new materials will be developed towards high efficiency, high performance (including good weldability) and environmental benefit. Welding will develop better welding process, developed a better welding power supply and develop the corresponding control technology, improve the degree of automation and expand the application scope of the robot: reduce the scrap rate and repair rate, reduce the welding cost, improve the production efficiency (such as: reduce, after preheating, heat, avoid welding overheating, etc.), eliminate the concept of "welding is a manufacturing process obstacle".

Post time: Jun-18-2024