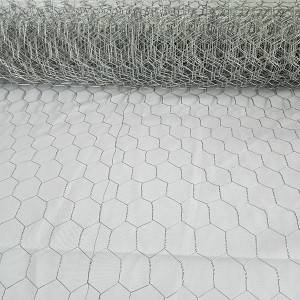

HIGH QUALITY HEXAGONAL WIRE MESH FENCING

Galvanized hexagonal wire mesh, we can also named galvanized hexagonal netting, galvanized chicken mesh, galvanized rabbit mesh or galvanized poultry mesh. Being made of low carbon steel wire, its special surface treatment, like galvanized, is anti-corrsive.

The galvanized hexagonal wire mesh is widely used in industry, agriculture, construction as reinforcement and fencing. For example, be used as light fencing for poultry, farms, for birds, rabbits and pet enclosures, tree guards and garden fencing, storage bins and decorative supports tennis courts. It is also used as wire mesh fabrics for light reinforcement in splinter proof glass and cement concrete, plastering and laying of roads, etc.

Galvanized hexagonal wire mesh is formed by twisting two adjacent wires at least four times, forming a strong honeycomb mesh structure. So, it has a high strength and durability.

Even if a place is cut off, it will not lead to the entire chicken mesh structure destroyed. When

using for plastering, plaster layer and the reinforcing metal layer have different thermal

expansion coefficient.

Material:

High quality low carbon steel wire.

Processing mode:

Twist, reverse twist, double sided twist.

Surface treatment:

electric galvanized before weaving,

hot-dipped galvanized before weaving,

hot-dipped galvanized after weaving.

The hexagonal wire mesh can be also be made with PVC coated, usually is green color..

The specifications can be customized according to your special requirements.

| Opening(mm) | Wire diameter (mm) | Wire Diameter (PVC Coated) | Size(m) |

| 60x80 | 2.0-2.8 | 2.0/3.0-2.5/3.5 | 1x1x0.3 1x1x0.5 |

| 80x100 | 2.0-3.2 | 2.0/3.0-2.8/3.8 | 2x1x0.3 2x1x0.5 |

| 80x120 | 2.0-3.2 | 2.0/3.0-2.8/3.8 | 2x1x1 4x2x1 |

| 100x120 | 2.0-3.4 | 2.0/3.0-2.8/3.8 | 6x2x0.3 6x2x1 |

| 100x150 | 2.0-3.4 | 2.0/3.0-2.8/3.8 | As your request |

| 120x150 | 2.0-4.0 | 2.0/3.0-3.0/4.0 | As your request |

Packing:

(1) Shrink film+ label

(2) Water-proof paper+ shrink film+ label

(3) Water-proof paper+ shrink film+label, then in pallet.

(4) Packing as customers' specific requirements.